The tea bag packing equipment does not have the outer roll position because it is designed for the inner bag with a string and label. The packaging process is similar to the second type above, but the final product will be transported out when it finishes the inner bag packaging.

| Production efficiency | 30-45 bags/minute (depending on the weight of the material) |

| Packaging weight | 5-12g (depending on the material characteristics) |

| Packaging error | ±0.2g (depending on the material characteristics) |

| Control system | PLC controller + color touch screen |

| Inner bag width & length | 120mm-180mm & 50mm-75mm |

| Outer bag width & length | 150mm-220mm & 85mm-150mm |

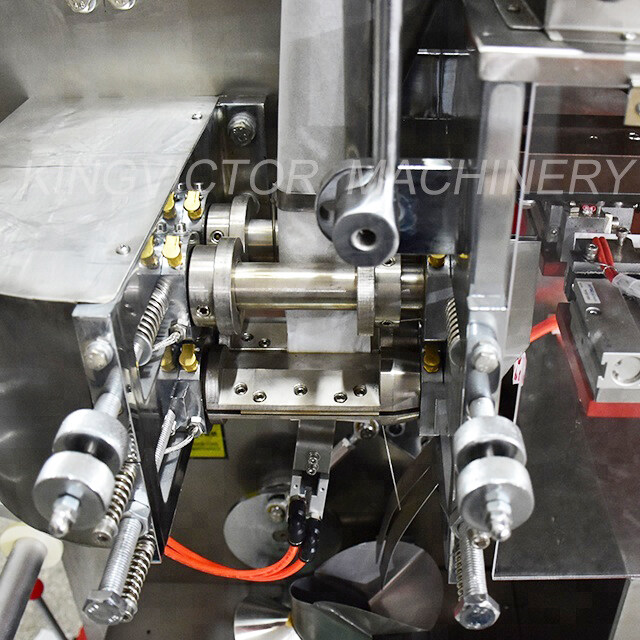

| Sealing method | Three-side sealing |

| Applicable packaging material | PP, PE, PVC, PS, EVA, PET, PVDC+PVC, OPP+composite CPP, etc. |

| Equipment power supply | 220v/50Hz/3.7kw |

| Air consumption | 0.35m3/min |

| Machine size (L.W.H) | 1345mm*779mm*2262mm |

| Machine weight | 650kg |

Application

This filling and sealing machine is suitable for filling powder materials, such as coffee powder, milk powder, matcha powder, milk tea powder, nutritional powder, cocoa powder, ginseng powder, etc.

Kindly Reminder

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Please tell us the following information when you send us an inquiry. Based on your message, we will suggest the optimum solution to you for reference. Thank you.

Packing Exambers

Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent